Is it Mackies, Union, Depoortere or Van Hauwaert – the mystery of who made the flax scutcher?

Scutched Flax Fibre

What is scutching?

Scutching is the process of taking off all the outer parts of the flax plant to leave the long fibres. We do this once the harvested flax has been retted, dried and broken using our old, refurbished flax scutcher. You can read more about the full process here.

Scutching is the process of taking off all the outer parts of the flax plant to leave the long fibres. We do this once the harvested flax has been retted, dried and broken using our old, refurbished flax scutcher. You can read more about the full process here.

In the past, scutching would have been a long, dusty, labour intensive process to do by hand. Over the years there have been a variety of machines developed for the job; from simple wooden paddles for hand scutching to water driven turbines. These were extremely dangerous and many injuries resulted from people having to come into contact with fast moving turbine blades. After this, in the 1930’s a new type of scutching turbine was developed. It was more efficient and less dangerous than its water driven predecessors.

A few years ago we were lucky enough to find and buy a 1940’s flax scutcher. It was in pieces.

This beautiful machine had been in operation in a mill in the area up until the 1980’s. It had passed the many years since then stored in a barn. All the fibre we produce has been scutched by this amazing machine, now up and running again after its forty year rest.

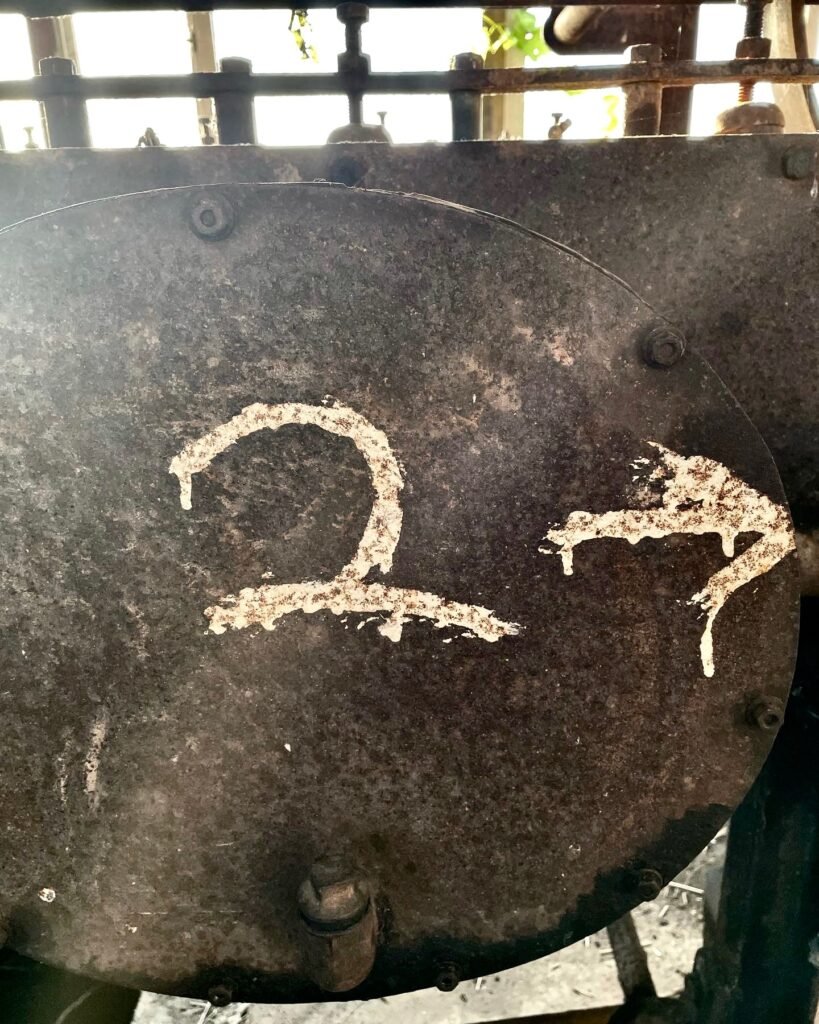

It’s been the biggest jigsaw puzzle we’ve ever done. We were relieved to discover that whoever had taken it apart at some point, had helpfully numbered some of the pieces. The scutching machine firstly breaks the dried flax in a set of metal breakers. As the flax travels through the machine, the outer core is removed leaving long, flexible fibres.

We think our machine was designed by Van Hauwaert, a family owned Belgian company that have been making machinery since the 1890’s. They helped us so much with our restoration by sourcing belts for the machine.

But we also see some Mackie’s plates. The amazing linen researcher, Sebastian Graham of Mills of Northern Ireland sent us this newspaper cutting from 1941 which suggests it could have been designed by Van Hauwaert but built by Mackies.

This all seemed to fit until one Robert Kidd came to visit. He worked for years in flax growing and processing and knew all the machinery. He pointed to some very old flaking paint and assured us that our breakers had been made by Union and the turbines had been made by De Poortere.

It all adds to the puzzle and unique character of this mighty machine, but we don’t really mind as long as it works!

And it does, beautifully.